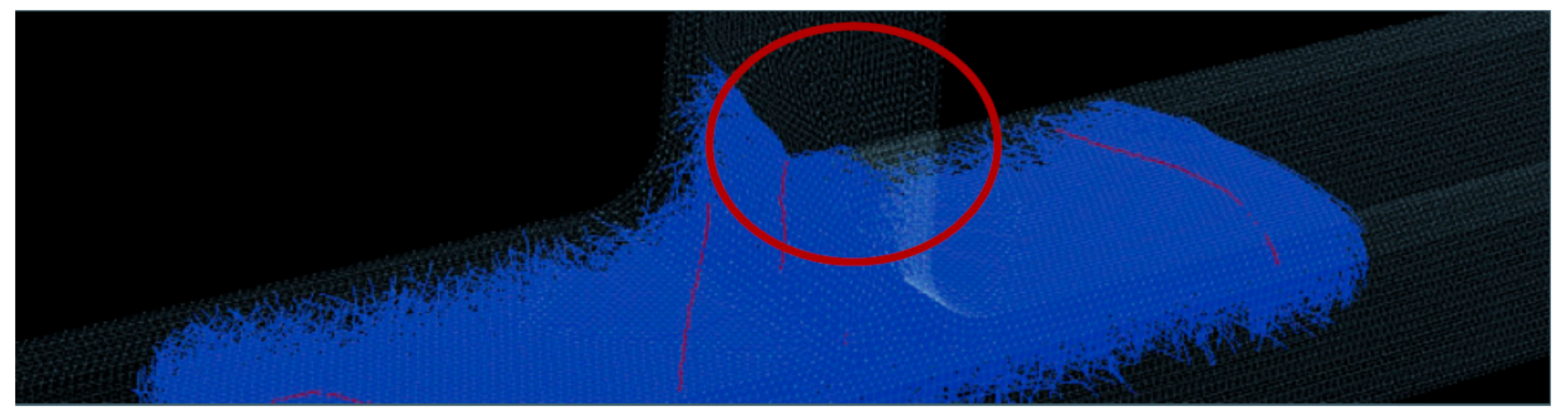

Fiber movement during compression molding simulations with the ribbed

By A Mystery Man Writer

Download scientific diagram | Fiber movement during compression molding simulations with the ribbed plate at consecutive time steps 1-4. from publication: Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation | Compression molding of long fiber reinforced composites offers specific advantages in automotive applications due to the high strength to weight ratio, the comparably low tooling costs and short cycle times. However, the manufacturing process of long fiber composite parts | Fiber, Compression Molding and Reinforcement (Psychology) | ResearchGate, the professional network for scientists.

PDF) Simulative Prediction of Fiber-Matrix Separation in Rib Filling During Compression Molding Using a Direct Fiber Simulation

Olaf TAEGER, Head of Polymers, Volkswagen AG, Wolfsburg, VW Group Reserach

Olaf TAEGER, Head of Polymers, Volkswagen AG, Wolfsburg, VW Group Reserach

Ian WALTER, Research Assistant, University of Wisconsin–Madison, Wisconsin, UW, Department of Mechanical Engineering

Christoph KUHN, Research Project Manager, Dr.-Ing., Volkswagen AG, Wolfsburg, Group Research

Mechanism of air-pumping noise.

J. Compos. Sci., Free Full-Text

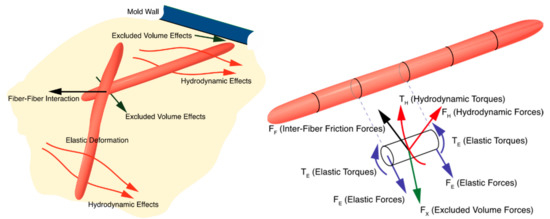

Depiction of forces and interactions calculated by direct fiber

J. Compos. Sci., Free Full-Text

- Cumpleaños Feliz (versiones instrumentales), Feliz Cumpleaños - Qobuz

- Por qué les gusta tanto el sol a los gatos?

- Robert Matthew Faux Leather Leggings - Bodacious High Waisted Tummy Control Fashion Leggings for Women, Womens High Waist Skinny Pants, Black Stretchy

- PRO Design Honeycomb Performance Mesh Grille for Honda Civic 21 20 19 18

- Victoria's Secret 32DD Bra Push Up Bombshell Nude Beige Floral