Wire Forming: What Is It? How Does It Work? Types & Uses

By A Mystery Man Writer

Multi-chapter guide to Wire Forming describing: what is a wire forming, how wire forming is done, types of wire forming, how wire formed wires are used.

Wire forming is a method for applying force to change the contour of wire by bending, swaging, piercing, chamfering, shearing, or other techniques. The various techniques for wire forming can produce any type of shape, form, or configuration. The process starts with coiled wire that is straightened before being formed. Common metals used for wire forming include steel, brass, stainless steel, copper, aluminum, and a variety of different alloys. The diameters of wires vary from 0.5 mm to 6.5 mm, or 1/64th of an inch to a quarter inch and can produce 2 and 3 dimensional wire forms. The types of equipment to complete wire forming vary between manual crafting to advanced CNC programmable machines. The process includes options for coating and protecting final products for use in harsh conditions.

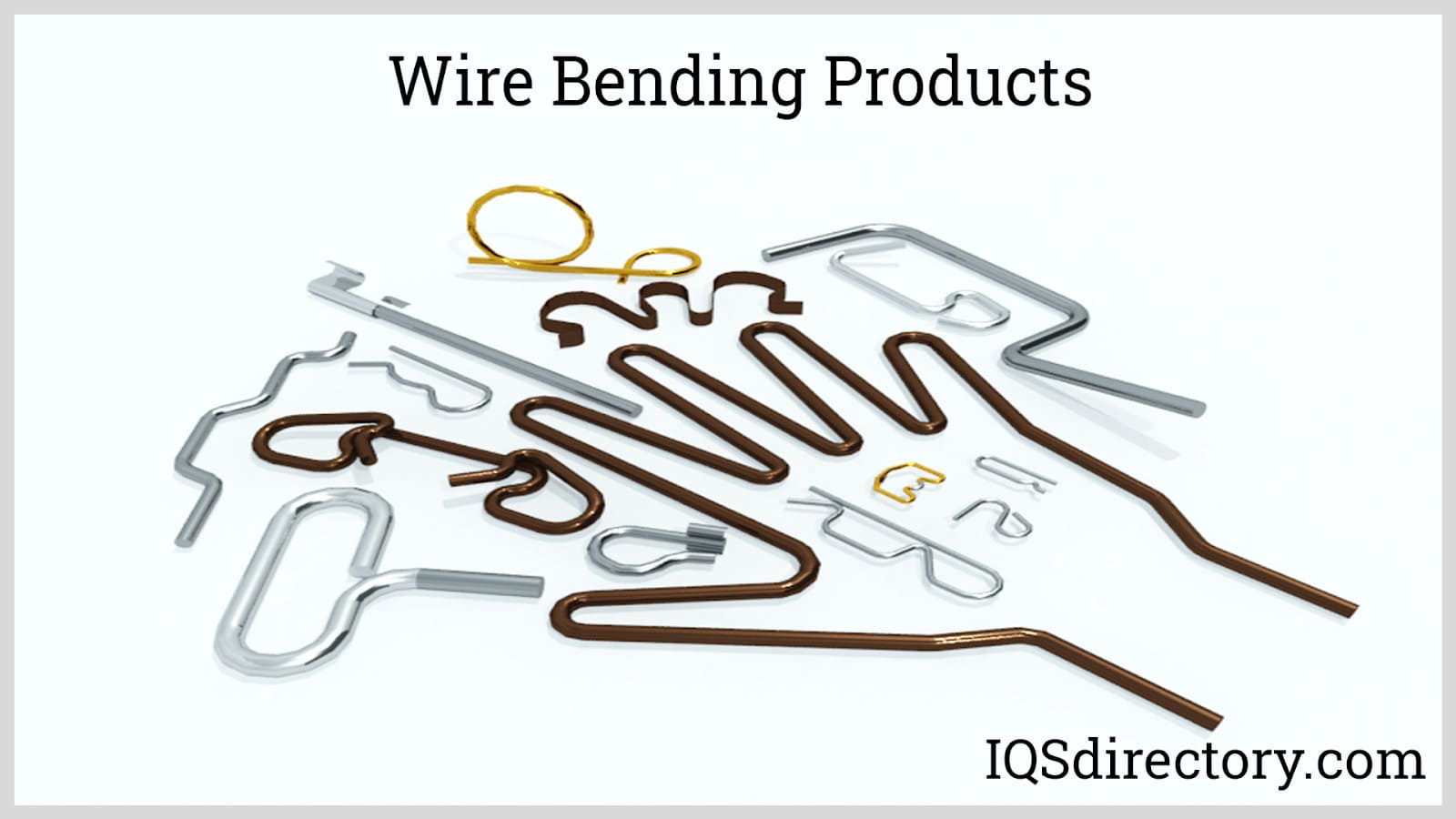

Wire Bending: What are the benefits of using wire forming products?

Types of Wires & Cables

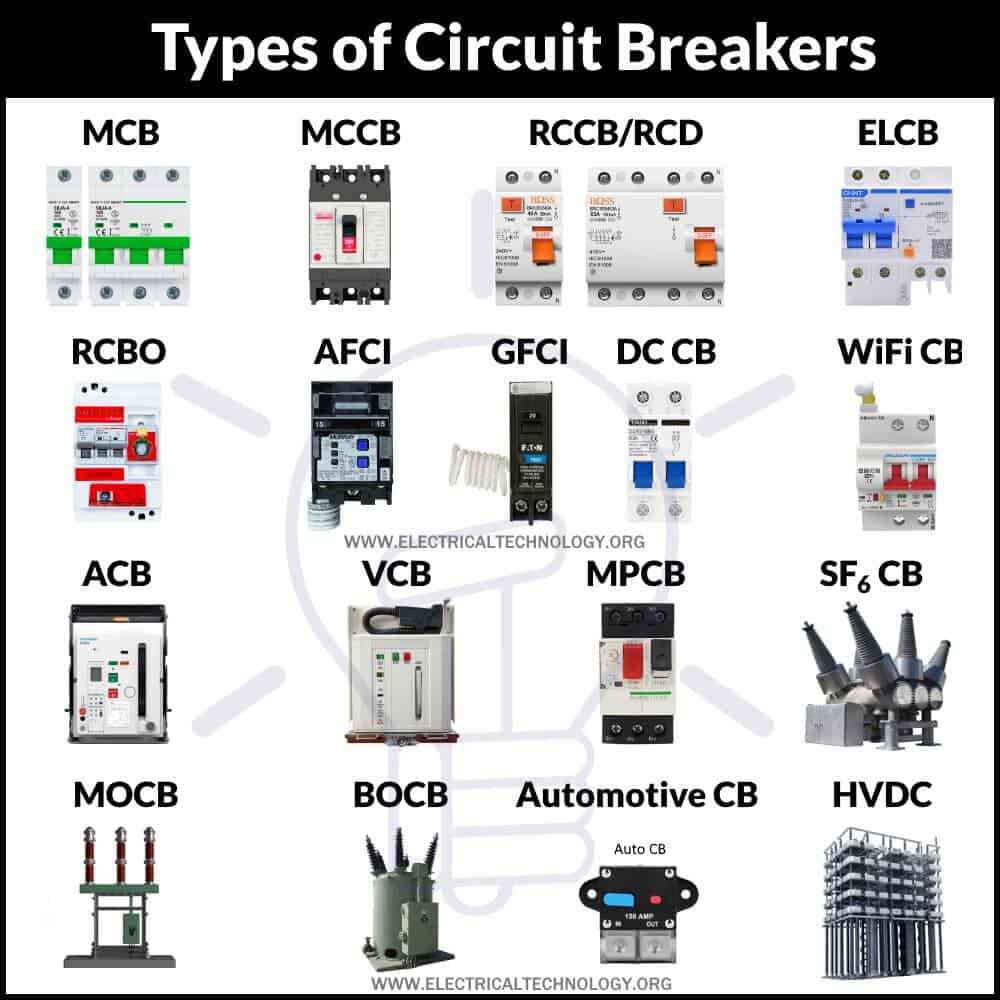

Types of Circuit Breakers - Working and Applications

Tyau Yang Spring Co., LTD. - Wire Form Springs

Types of Conduit - The Home Depot

What is Wire Forming and How do Wire Forming Machines Work?

Wire Working Basics: How to create beautiful shapes from wire.

The Complete Guide To Wire Forms Applications And How To Use Them

What is Wire Forming

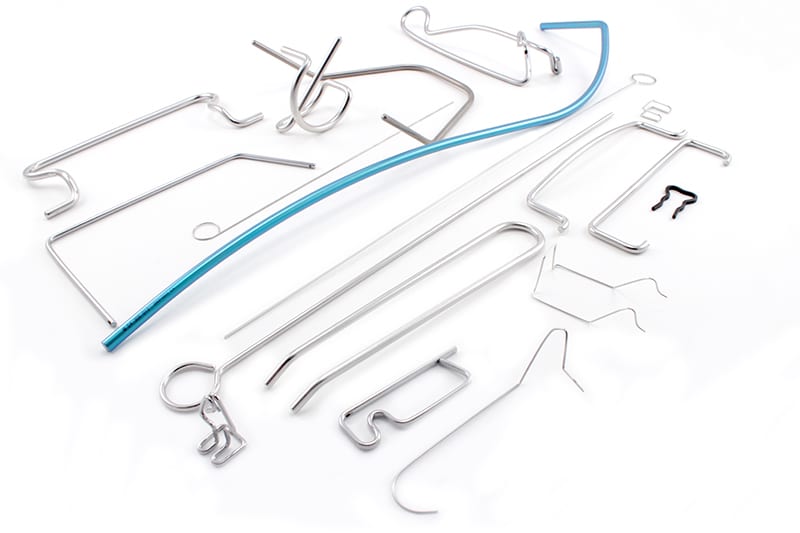

Wire Forms Basics - Fabrication, Applications & Materials

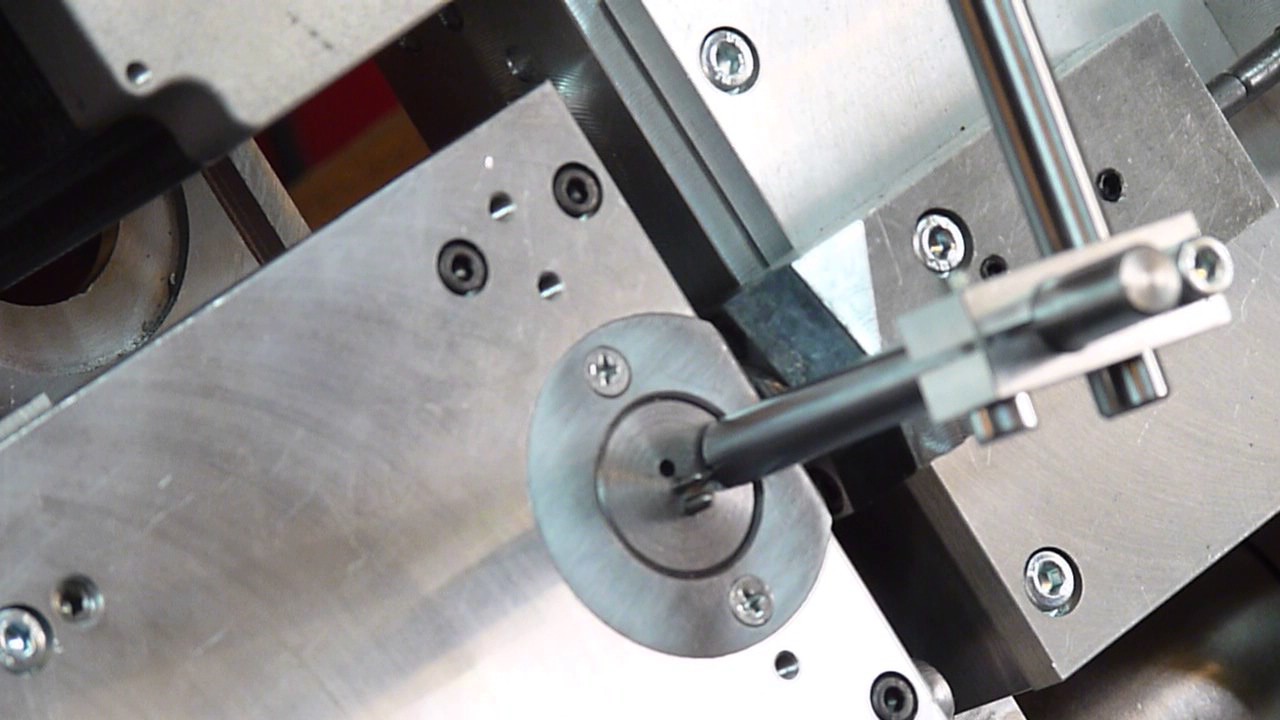

Importance of CNC Wire Forming

Network cable connectors come in many forms for different networks by networkpatchpanel - Issuu

Electromagnetic coil - Wikipedia

USES OF WIRE BENDING MACHINES IN DIFFERENT INDUSTRIES, by Autolink

- Adrienne Vittadini Beige Bras for Women

- Calça Legging Cirre com Zíper No Joelho Plus, Calça Feminina Nf Nunca Usado 53830053

- NORRONA Lyngen GORE-TEX PRO Pants Women 2048-18 Indigo Night

- Petrol Blue Stretch Fitted Bust Strappy Cami Top

- Women's Long Sleeve Satin Shiny Jumpsuit 2-Way Zipper Bodysuit Catsuit Clubwear