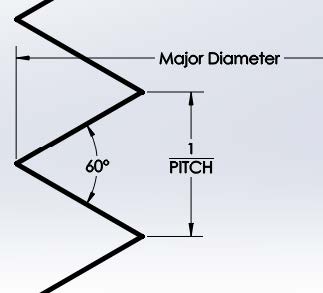

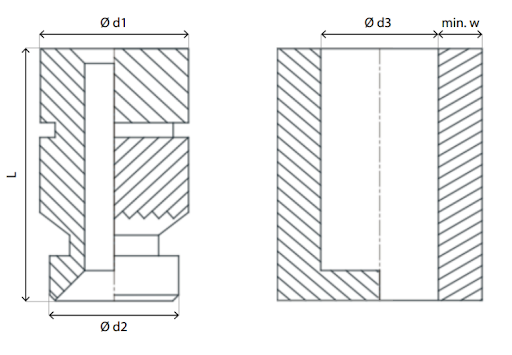

Threaded Holes: An Introduction and Guidelines

By A Mystery Man Writer

Threaded holes are integral aspects of mechanically fastened parts. They are easy to add with CNC machines. Threads are usually added last after most other aspects of the part have been machined. Getting it wrong and being forced to scrap a part can be a very costly mistake. There are several factors designers and machinists must consider when they approach threaded components. Careful planning along with the following guidelines will make the addition of threaded holes go smoothly.

Pocket Hole Screw Guide - Free Printable!

Threaded Inserts for Vans (Crossnut & Rivet Nut)

Design Guidelines — Jax Precision

Drill Guide- 4.5mm - TribeVet

Make Threaded Holes: Considerations For Tapped A Hole - WayKen

USED* 52454-SINGER-3 HOLE THREAD GUIDE FOR SEWING MACHINES*

CNC Machining Threaded Holes Guidelines for Milling & Turning

AMT Wood Tap and Die Threading Instructions Owners Guide Booklet

Door guide 100 x 36,2 x 7,6 mm, inner part, steel galvanized

2pcs #52454 Thread Guide(3hole) For Singer 96k, 20u,31 Class,391a1

Rack Hole Size Differences: Square hole vs Round vs Threaded

Feasibility of Threaded Holes for Rapid Prototyping

Threaded Inserts Guide - MJF/ FDM Printing

Lag Screw Pilot Hole Sizes for Wood

Patent]CKE 30 45 90 Degree Angle 4 Sizes Drill Hole Guide Jig with