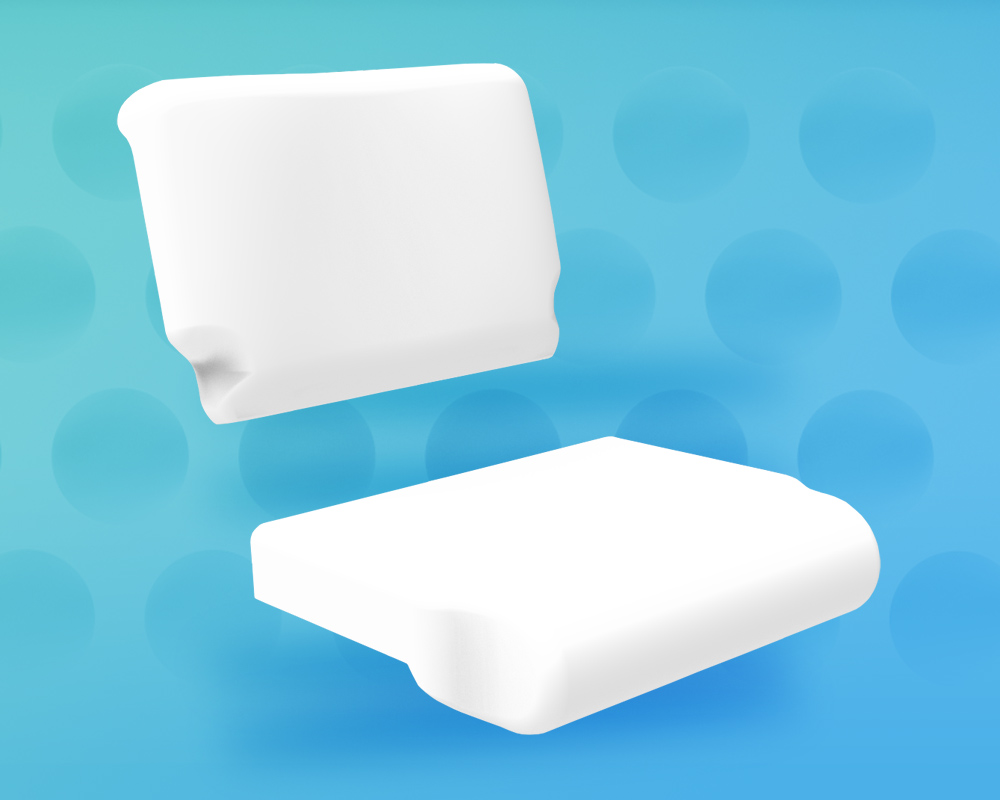

3D Printed Tooling Supports Prototype Foam Seating

By A Mystery Man Writer

3D printed tools could be a faster, more affordable way to prototype and produce foam parts for automakers and other OEMs.

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

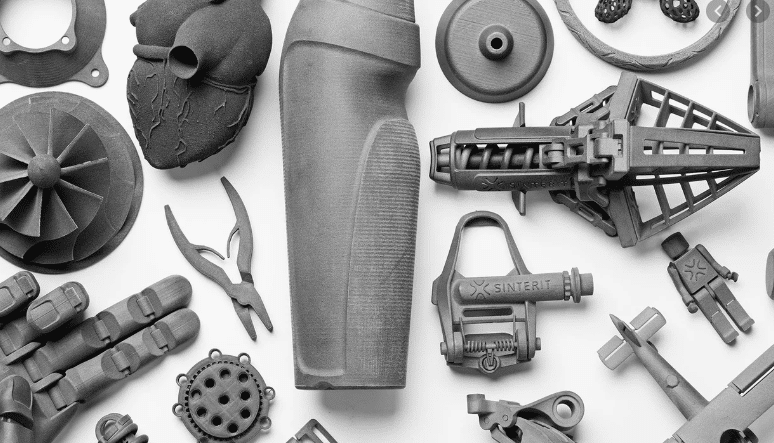

SLS 3D Printing: The Knowledge Series

Students Create “Breathing” Audi Car Seat with 3D Printing

Stock Up With Wholesale polyurethane foam prototype Online

3D Printing at the Turn of Iten's Century

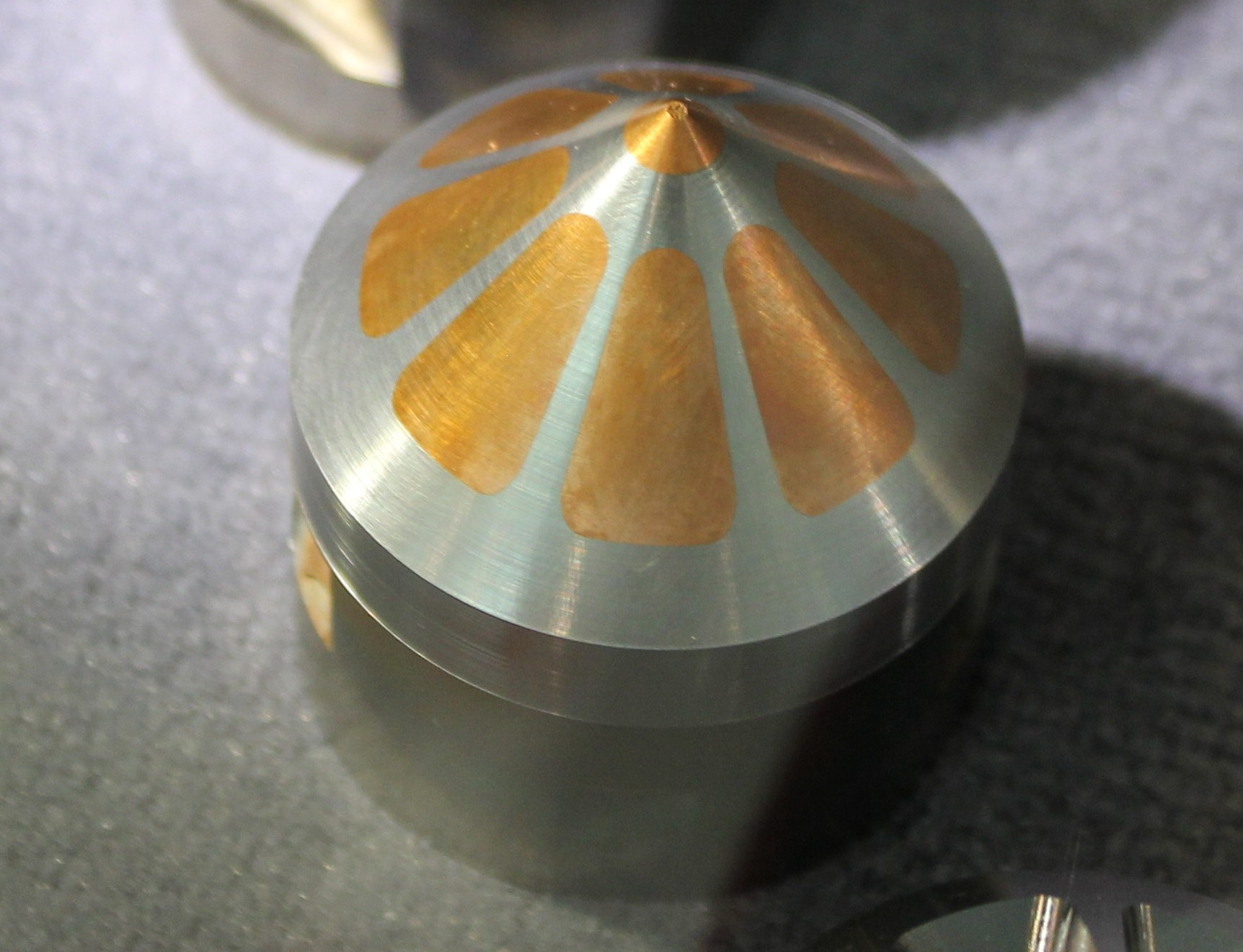

Tool Steel Alloy Combines 3D Printability with Hardness, Ductility

3D Printed Kneepad in TPU 85A

Advanced support removal techniques

Hermle Combines Metal Powder Application Process with Five-Axis

An Injection Molder in MMS?

- Breastfeeding Eat Local Bodysuit Nursing Toddler Shirt Funny Baby

- 28FF Bra Sale, Bra Sets & Bralette Sale

- Hum Gilgit Baltistan K hain Songs Download, MP3 Song Download Free Online

- Plus Size Women's Suits Mint Green Mother of the Bride Blazer Pants Formal Prom

- Adore Me Avara Women's Corset Regular Sizes