O-rings norelem FR

By A Mystery Man Writer

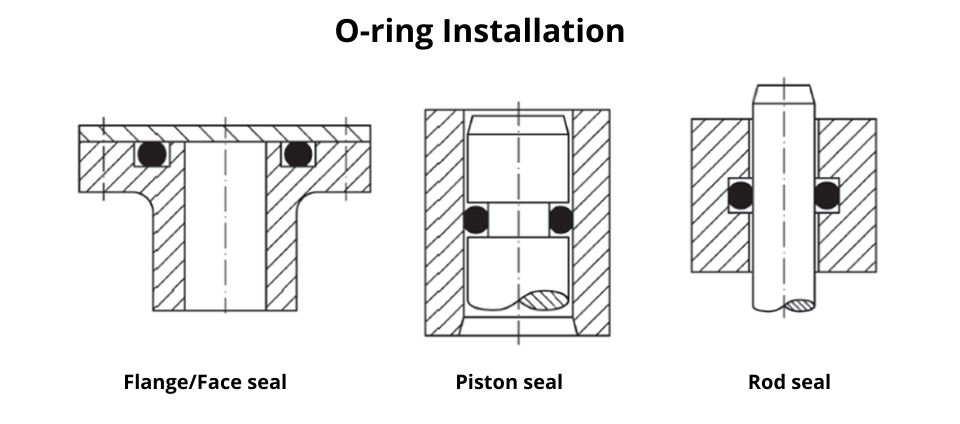

O-rings are universal sealing elements used to seal against liquid or gaseous median. They are suitable for static and minor dynamic applications. O-rings can be used for radial and axial sealing. The sealing occurs during installation by the radial or axial compression of the cross-section. During operation, the median pressure increases the deformation of the O-ring and so increases the sealing effectiveness. For best sealing effectiveness, the O-ring should have the largest possible cross-section. During installation the correct groove size, compaction, elongation/compression should be ensured. By static use the compaction should be 15 - 30% of the cross-section. By dynamic use it should be 10 - 18% (hydraulic), 4 - 12% (pneumatic). With regard to the ID, when installed the O-ring should be stretched max 6% compressed max 3% The material NBR has a high wear resistance and is resistant to mineral oil based lubricating oils and grease, hydraulic oils (H, H-L, H-LP), high-flashpoint pressure fluids (HFA, HFB, HFC), aliphatic hydrocarbons, silicon oil and grease, water up to ca. 80° C

Self-Aligning Pad with o-ring high carbon steel tempered, black

Élingue d'arrimage FTC O'Ring 2

O-rings norelem FR

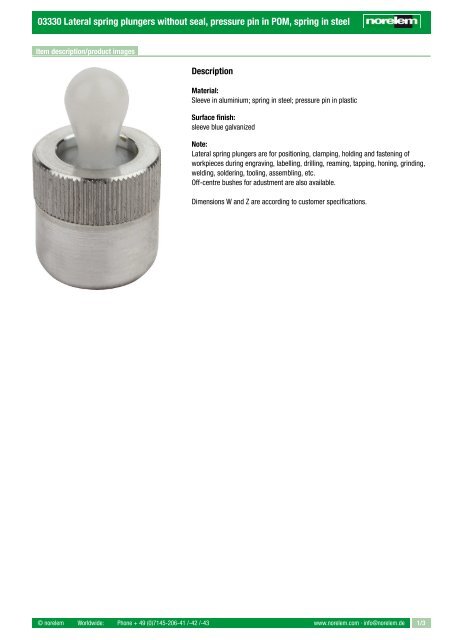

03330 Lateral spring plungers without seal, pressure pin - norelem

1048.500 - V-Blocks /

Hoist rings

22430 Bevel gears in steel, ratio 1:1 toothing milled - norelem

O-ring NORMATEC® en NBR 70.00-01

Self-aligning pads, adjustable, with O-ring, Form F, flattened

Din 471 Steel Safety Rings Din 471 Ref. Norelem 07330-080800

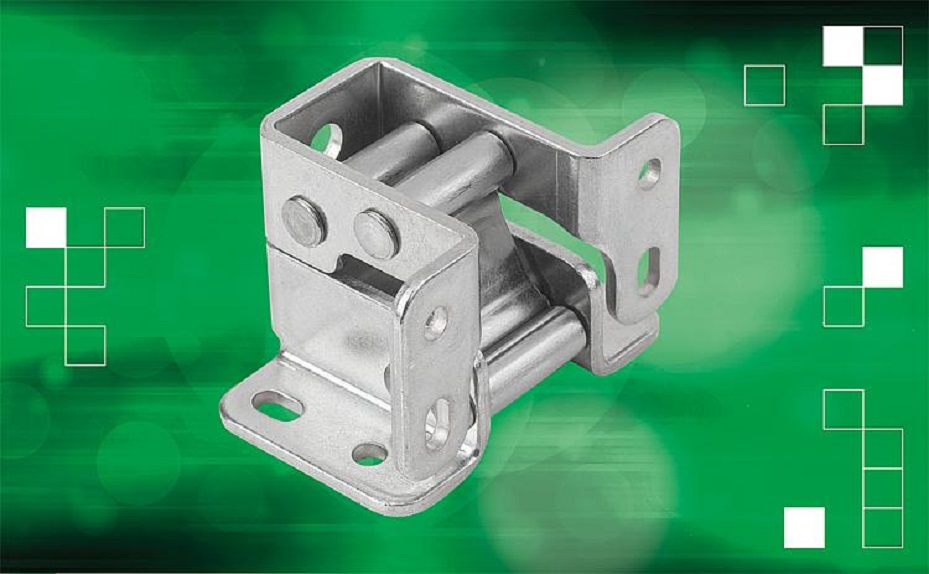

Recessed hinges - Industrie online

MOEN Assorted O-Rings 5 Sizes

O-rings norelem FR

- Youngla Longsleeve Muscle Shirt - Gem

- Moisture Wicking Cotton Panties-Women's Panties, Single Guide Wet Antibacterial Bottoms, Green, XL : : Clothing, Shoes & Accessories

- Durtebeua Bras For Women Full Coverage Moisture-wicking

- M&S launches inclusive range of nude underwear featuring darker

- Easy summer style: Stylish tops to wear with leggings