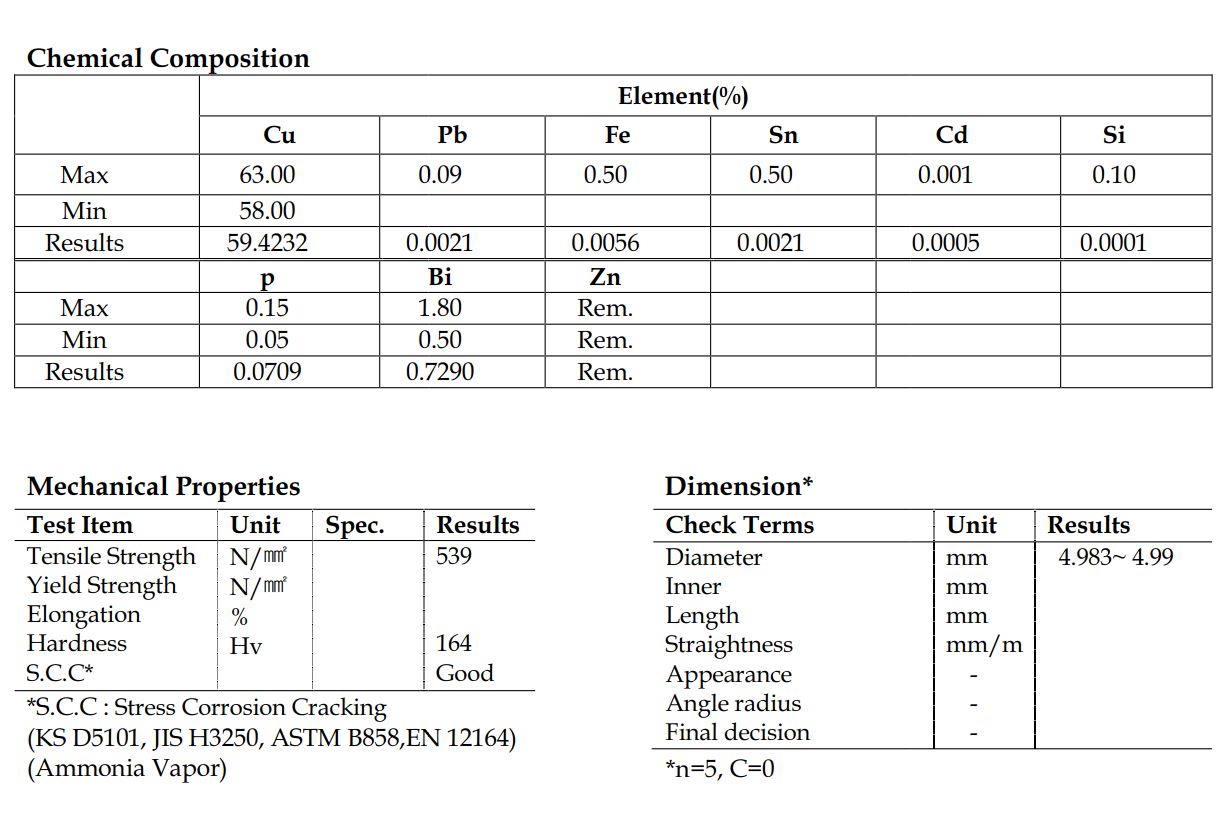

Chemical composition of the lead-free brass

By A Mystery Man Writer

Download Table | Chemical composition of the lead-free brass from publication: Modified Johnson–Cook flow stress model with thermal softening damping for finite element modeling of cutting | Results of materials testing for lead-free brass show that the effect of thermal softening decreases significantly when the strain rate is high. This behavior is referred to as thermal softening damping. In this article, a flow stress model with thermal softening damping | Damping, Thermal and Finite Element Modeling | ResearchGate, the professional network for scientists.

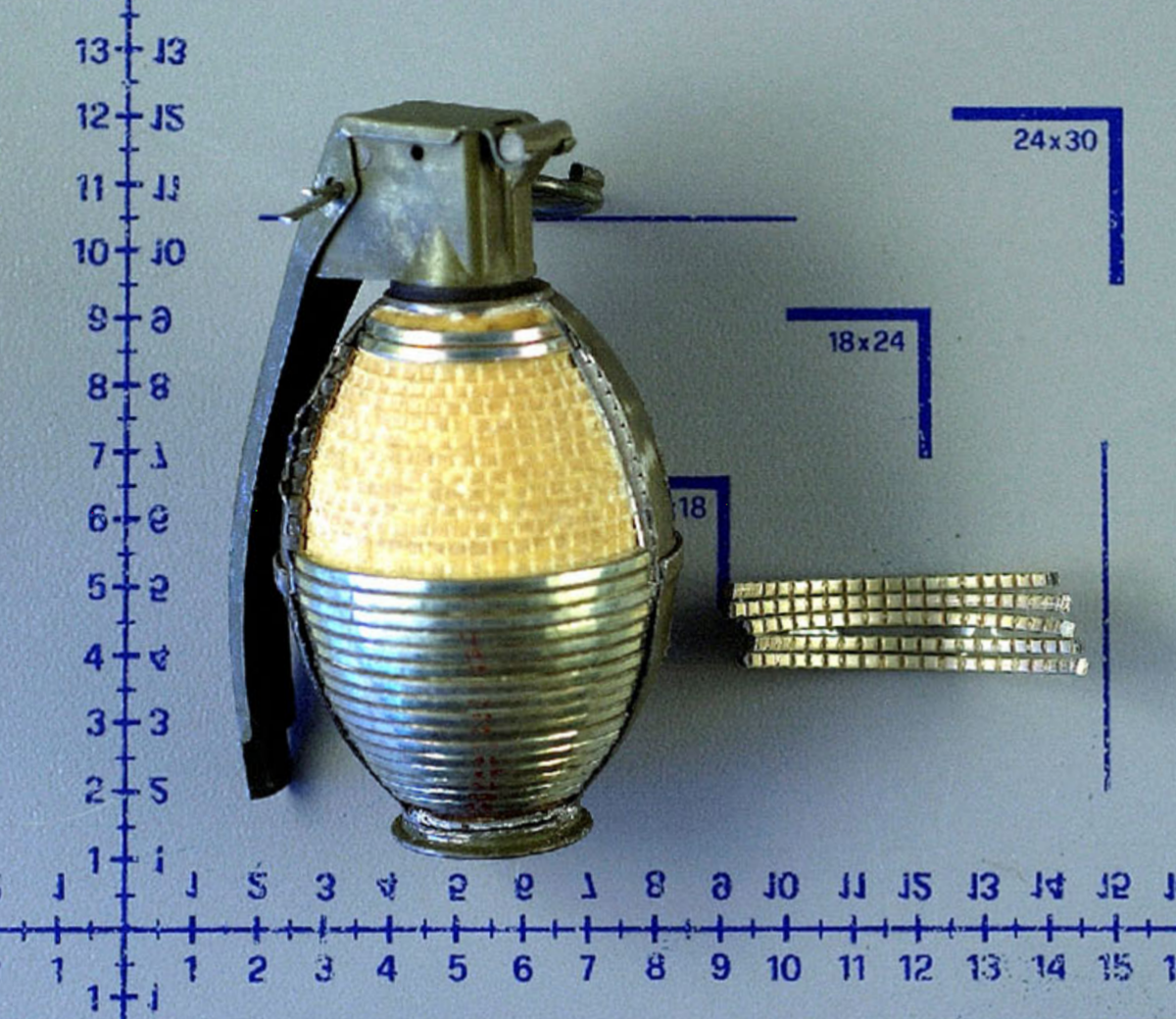

PDF) Investigation of the effect of different cutting parameters on chip formation of low-lead brass with experiments and simulations

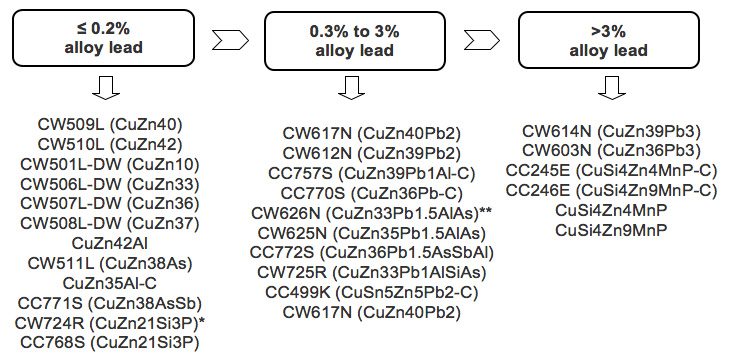

Lead Free Brass Alloys - Benefits, Uses and Composition

C4926 Lead-free Brass Rod - Products

UBA list – entry into force of alloys compliant with the drinking

Material Physical Properties

Senor Lead Free Brass

Compression stress strain curves obtained at different temperatures and

Meridional stresses in concrete (under ultimate loads).

Hoop stress distributions in concrete for tanks T7, T8, and T9 (under

Lead Free Brass Manufacturer

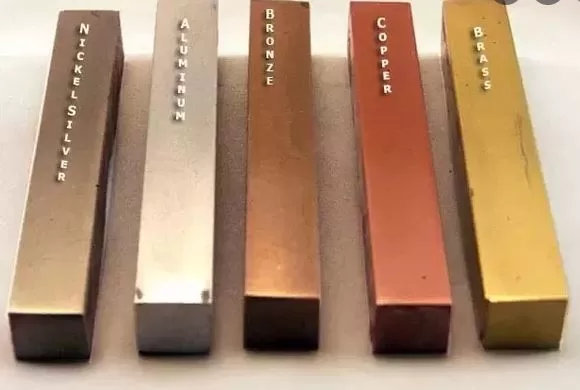

Brass: Composition, Properties & Uses